Product Center

Leave a message online

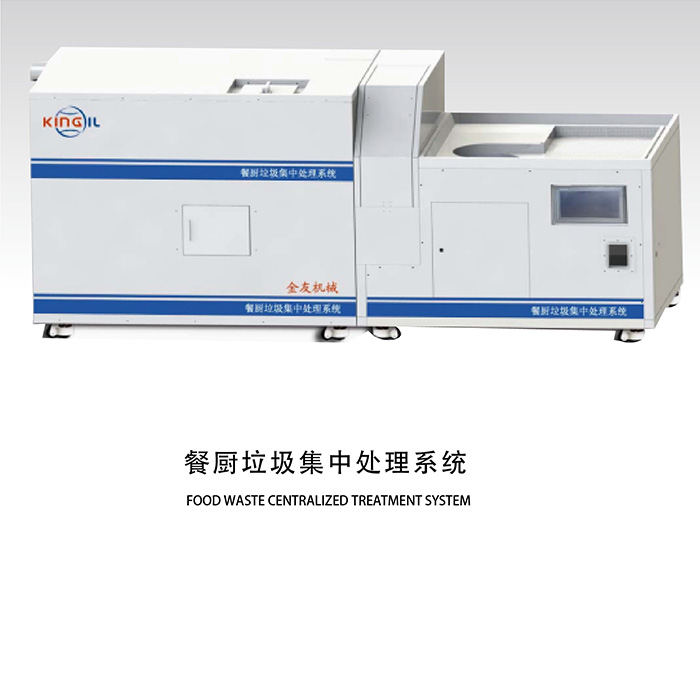

The centralized kitchen waste treatment system is composed of a solid-liquid separation system, an oil-water separation system, a bacterial fermentation system, an air purification system, a sewage treatment system, a PLC intelligent control system, and an Internet of Things remote monitoring system. Through solid-liquid separation and oil-water separation technology, the solid and liquid in the kitchen waste are separated, and then the oil and water in the liquid are separated. The oil can be collected uniformly to make biodiesel, and the water is treated by a professional water treatment system before it is discharged in compliance with the standards; the solid part is cut, ground and crushed to form relatively uniform garbage particles, and bacteria are added under a constant temperature environment, which are completely degraded through biological fermentation and finally converted into organic fertilizer; the gas produced by bacterial fermentation is adsorbed and filtered through multiple layers such as activated carbon and ion layer, combined with UV light deodorization and sterilization, which completely solves the odor and air pollution problems.

The product is highly integrated, versatile and intelligent, with functions such as automatic lifting, solid-liquid separation, oil-water separation, biochemical treatment, air purification, automatic discharging, PLC intelligent control and IoT remote monitoring, which can effectively achieve the "reduction, harmlessness and resource utilization" of kitchen waste.

Performance of centralized kitchen waste treatment system:

1. Adopt a set of solutions and a centralized treatment system to treat restaurant kitchen waste in a one-time and harmless manner, thus realizing resource recycling;

2. It can automatically feed materials, reduce labor by about 50%, and improve efficiency; the shredder replaces the crusher and can handle larger and harder materials;

3. The combination of activated carbon and UV photolysis can more effectively eliminate air odor and purify the air;

4. Use biochemical bacteria, which has short processing time, high efficiency and high efficiency of organic fertilizer;

5. Integrate the biochemical treatment system and air purification system to reduce the overall volume and enhance the kitchen waste treatment capacity;

6. Use PLC intelligent control and Internet of Things remote monitoring technology to achieve real-time online monitoring and fault diagnosis of food waste treatment equipment.

Related Products