Product Center

Leave a message online

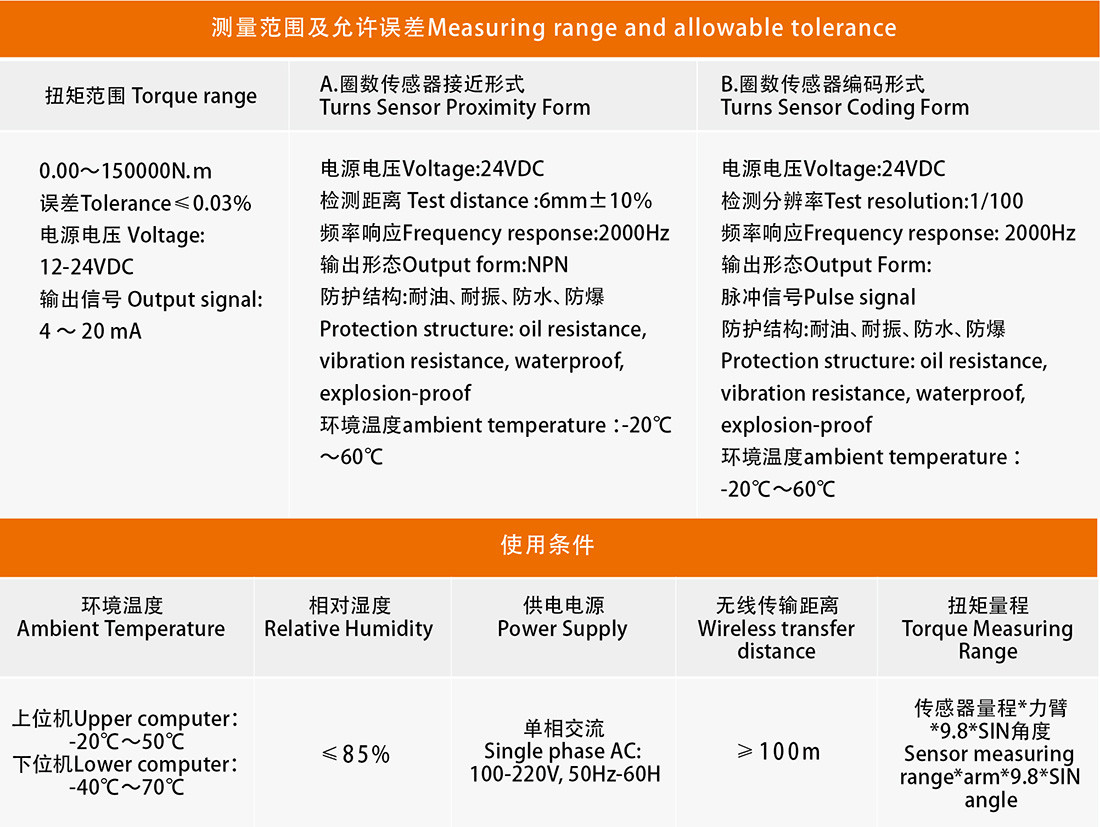

In oil drilling projects, the quality of casing cementing operations plays a very important role in wellbore safety. NJY/YT oil and casing intelligent torque monitoring system is widely used in various types of oil and casing power tongs, realizing real-time monitoring and control of oil and casing make-up process, ensuring the quality of oil and casing operations. It has a good human-machine interface, powerful data acquisition and control functions, as well as torque, speed, and curve display, making it very easy for customers to set make-up parameters, thereby achieving precise make-up control and quality evaluation.

Features

01 Real-time detection of torque, number of turns and rotation speed during the make-up process. The collected data is transmitted wirelessly (or wired) to the intelligent torque controller protector and portable computer respectively.

02 The make-up torque can be set. When the measured torque value reaches the set upper limit, the relay will be activated and the overflow valve will release the load. At the same time, the sound and light alarm will sound.

03 After the make-up is completed, parameter analysis is performed to compare the actual results with the torque and number of turns pre-set by the customer, allowing the customer to enter recommended parameter values, comments or self-selected parameters.

04 Extract previous relevant make-up parameters

05 Real-time parameter monitoring and curve printing of the entire make-up process.

06 Generate detailed work reports, analyze reports and archive them.

07 Assist operators to perform routine and accurate torque and speed calibration and calibration records.

Related Products